Home > Quality

Testing Equipments

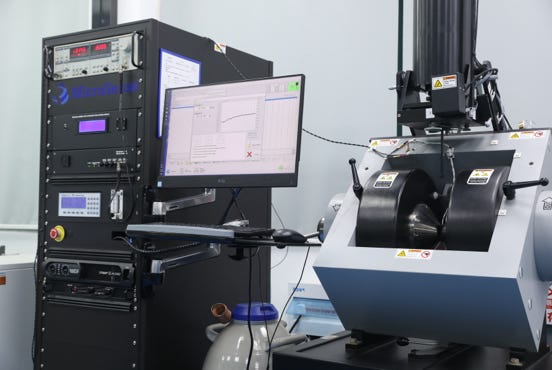

VSM stands for Vibrating Sample Magnetometer, which is an experimental instrument used to measure the magnetic properties of magnetic materials. It can measure properties such as the magnetization curve and hysteresis loop of a sample. The VSM can be used to study the magnetic characteristics of a sample by varying the size and direction of the applied magnetic field.

Scanning Electron Microscope is an instrument that can produce high-resolution, high-magnification 3D surface morphology images. It scans the sample surface using an electron beam and detectors to obtain information about the surface morphology and microstructure. The SEM can acquire detailed surface information of the sample at different magnifications.

A Pulse Magnetic Field Magnetometer is an experimental instrument used for measuring magnetic field strength. Unlike a static magnetic field magnetometer, a pulse magnetic field magnetometer can generate very high-intensity transient pulse fields, typically reaching strengths of several hundred teslas, in order to measure the magnetic properties of materials under high saturation magnetic fields.

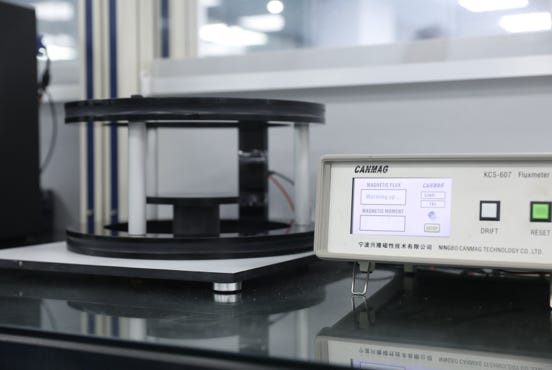

A flux meter is a device used to measure the magnetic flux. The magnetic flux is a physical quantity that represents the total amount of magnetic field passing through a plane or curved surface, usually expressed in units of Weber. The flux meter can calculate the value of magnetic flux by detecting the magnetic field intensity and measuring the area covered.

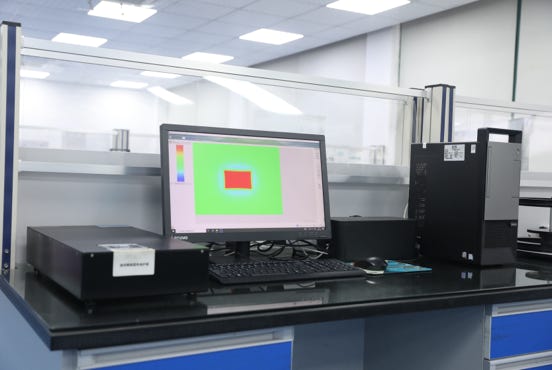

CMOS Magview Display the high-resolution image of the invisible magnetic field on a computer monitor.

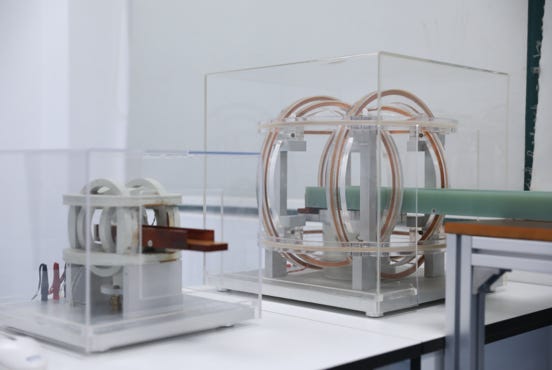

A three-dimensional magnetic field tester is a device used to measure the strength and direction of magnetic fields in three-dimensional space. The data acquisition and processing system is responsible for converting the magnetic field data collected by the sensors into digital signals, and processing, filtering, and analyzing them to ultimately obtain numerical results for the magnetic field strength and direction.

High-precision measurement with a resolution of 0.1uVs can measure magnetic flux and moment, and can also be used to test magnetic field q.

The ICP analyzer is an advanced analytical instrument, also known as an Inductively Coupled Plasma Atomic Emission Spectrometer (ICP-AES), which is primarily used for quantitative analysis of elements in chemical analysis. Its operating principle involves exciting the sample through a plasma to produce an emission spectrum, and detecting specific wavelengths in the emission spectrum to determine the content of each element in the sample.

A high and low temperature test instrument is a device used to simulate high and low temperature environments, for testing the performance and reliability of magnetic materials. It ensures that the magnets we produce can function normally and have a long lifespan in extreme temperature conditions.

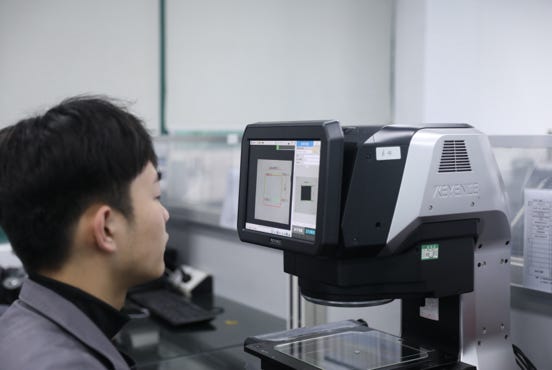

Keyence Image Dimension Measurement System It is an image-based dimension measurement instrument that utilizes image processing technology to quickly and accurately measure various shapes and sizes of workpieces.

CCD visual inspection equipment is an automatic inspection system based on image processing technology, which is mainly used for quality inspection and control of workpieces. It is mainly composed of CCD camera, light source, lens, processor, etc., and realizes automatic detection and judgment of workpieces by capturing images, image processing and analysis.

The salt spray test machine is used to test the corrosion resistance of the product coating, and it is the most intuitive method to test the bonding force of the product coating.

ONH-3000 has the characteristics of high precision, high stability, fast analysis, etc. It is used for content analysis of oxygen, nitrogen, hydrogen and other elements in test materials and evaluation of material properties. By measuring the content of elements in materials, it provides important data support for material design and production.

It is an instrument used to measure the force on an object. A dynamometer measures the force on an object and displays it on a display. Some high-end force gauges can also record and store data for subsequent analysis and processing.

Coordinate Measuring Machine (CMM) is a high-precision three-dimensional measuring device that can be used to measure the shape, size and position of objects. It uses three mutually perpendicular axes (X, Y, Z axes) and a motion probe to obtain the spatial coordinate information of the target object, and converts the information into digital signals for data processing and analysis.

ESPEC's temperature test equipment is mainly used to simulate the performance and reliability tests of products in high temperature and low temperature environments. ESPEC's humidity test equipment can simulate the performance and reliability tests of products in high humidity and low humidity environments.

Permanent Magnet Tester (Permanent Magnet Tester) is a test instrument used to measure the properties of permanent magnet materials. The permanent magnet tester evaluates the performance of permanent magnet materials by measuring parameters such as magnetic field strength, magnetization curve, and coercive force of permanent magnet materials.

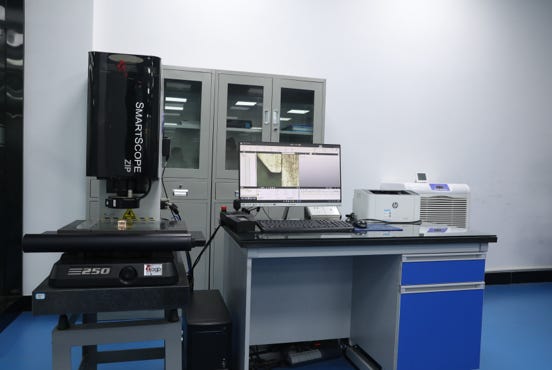

OGP optical projectors are used to measure the size, shape and surface properties of various precision workpieces.

The multi-pole magnetic field tester is used to test the uniformity of multi-pole magnetization of products, etc.

The RoHS tester is a device used to detect the content of harmful substances in electronic and electrical products. The RoHS tester can quickly and accurately detect the content of harmful substances in electronic and electrical products through chemical analysis, spectral analysis, mass spectrometry and other technologies, and judge whether it meets the requirements of the RoHS directive.

The magnetic declination tester is used to detect the orientation angle of the magnetic field of the product, and generally it cannot exceed 5%.

The three-dimensional magnetic field scanner adopts 128*128 matrix array Hall probes to scan the surface of the magnetic steel to quickly present the surface magnetic distribution. The software is compiled based on Python, and the analysis results are more intuitive and convenient.

Test blocks for metallurgical microscopy can be produced quickly with this device.

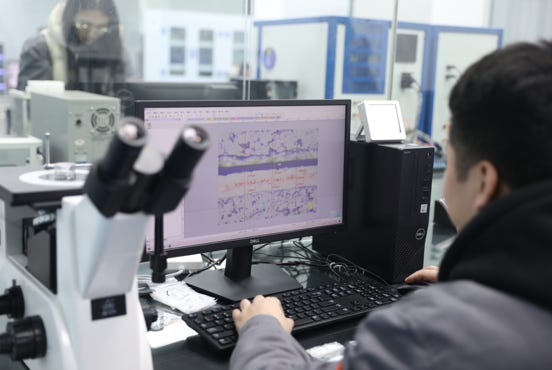

We use a high-resolution metallographic microscope to detect the coating thickness of the product, and can accurately measure whether the coating thickness of each layer meets the design requirements.

Certificates

ISO 9001

IATF 16949

ISO 14000

QC080000

ISO 45001

ISO 13485

Home

Capabilities

Solutions

Plating

Quality

Copyright @ 2024 Hangzhou Magmax Technology C., Ltd.